AAC Blocks

Largest Manufacturer Of AAC Blocks In India.

Why CONECC AAC Blocks?

High Quality

With our precision manufacturing, stringent quality control, and the use of top-notch raw materials, ensuring consistent durability and performance in diverse construction applications.

4 Different Sizes

600mm x 200mm x 100mm

600mm x 200mm x 150mm

600mm x 200mm x 200mm

600mm x 200mm x 225mm

Ribbed Face

CONECC Block comes with a unique ribbed finish on the face. It helps in better bonding of plaster with the blocks. Due to the ribbed face only, you can directly apply wall putty or Plaster of Paris without plastering.

Benefits Of Our AAC Blocks

Strong and Durable

CONECC AAC blocks surpass normal bricks in strength with a compressive strength of 3.5-4 MPa, a lower density for enhanced structural integrity, and advanced manufacturing processes ensuring durability under extreme conditions

4 times Lighter

CONECC AAC blocks are lighter than normal bricks due to their lower density and unique cellular structure, making them a more efficient and lightweight building material.

Fire Resistant

CONECC AAC blocks are fire-resistant because they are made from inorganic materials and undergo a high-temperature curing process during manufacturing, resulting in a composition that does not combust or contribute to a fire.

Ribbed Face

CONECC Block comes with a unique ribbed finish on the face. It helps in better bonding of plaster with the blocks. Due to the ribbed face only, you can directly apply wall putty or Plaster of Paris without plastering.

Eco-Friendly

Composed of 60% of Fly Ash, aerated concrete blocks have been certified to be one of the most ecological building materials.

Pest Resistant

Since CONECC AAC Block does not contain organic material, they will be protected from pests and long-lasting in normal atmospheric conditions.

Moisture & Damp Resistant

CONECC AAC blocks have a closed-cell structure, which means they contain tiny, closely packed air bubbles. These cells act as a barrier against the penetration of moisture.

Higher Earthquake Resistance

CONECC AAC blocks have higher earthquake resistance owing to their lightweight composition, uniform structure, excellent strength, ductility, interlocking design, and reduced dead load, collectively enhancing their ability to withstand seismic forces.

Sound Proof

CONECC AAC Block has perfect soundproofing properties due to its aerated structure preventing sound waves from crossing.

Houses That Are Built With CONECC AAC Blocks Are Resistant To Moisture.

Frequently Asked Questions

What Are AAC Blocks?

AAC (Autoclaved Aerated Concrete) blocks are special bricks made by mixing materials like cement, lime, fly ash, and water in the right amounts. This mix is then poured into molds and treated with high-pressure steam. The result is lightweight, strong bricks that are good at keeping your home insulated and are friendly to the environment. They’re great for construction because they’re easy to work with and contribute to making buildings energy-efficient and sustainable.

Why CONECC AAC Blocks?

CONECC AAC Blocks stand out for several reasons:

1. Quality Assurance: CONECC prioritizes quality, ensuring that its AAC blocks undergo rigorous testing and adhere to industry standards.

2. Innovation: CONECC employs advanced manufacturing processes and technology, staying at the forefront of innovation in the construction materials sector.

3. Lightweight Construction: CONECC AAC Blocks are lightweight, making them easy to handle and reducing the overall load on structures.

4. Energy Efficiency: These blocks offer excellent thermal insulation, contributing to energy-efficient buildings and reducing heating and cooling costs.

5. Strength and Durability: CONECC AAC Blocks undergo a special curing process, enhancing their strength and durability, ensuring long-lasting and resilient structures.

6. Environmental Friendliness: CONECC is committed to eco-friendly practices, and AAC blocks contribute to sustainability by using recycled materials and being energy-efficient.

7. Versatility: CONECC AAC Blocks find applications in various construction projects, offering versatility and adaptability to different building needs.

8. In-House Expertise: With over 15 years of experience, CONECC relies on the expertise of professionals in the field of AAC technology to deliver high-quality products.

Choosing CONECC AAC Blocks means opting for a reliable, innovative, and environmentally conscious solution for your construction needs.

Uses Of AAC Blocks?

AAC (Autoclaved Aerated Concrete) blocks find applications across various construction projects due to their versatile and beneficial properties. Here are some common uses of AAC blocks:

Residential Construction: AAC blocks are widely used in residential buildings for walls, floors, and roofs. Their lightweight nature facilitates easier construction, and their thermal insulation properties contribute to energy-efficient homes.

Commercial Buildings: AAC blocks are suitable for constructing commercial structures such as offices, malls, and hotels. Their versatility allows for the creation of durable and well-insulated spaces.

Industrial Buildings: The strength and durability of AAC blocks make them suitable for industrial structures where robust construction is essential.

Partition Walls: AAC blocks are often used for internal partition walls in both residential and commercial buildings. Their lightweight nature simplifies the construction process.

Exterior Walls: AAC blocks serve as excellent materials for exterior walls, providing insulation and contributing to the overall energy – efficiency of a building.

Load-Bearing Walls: Due to their strength, AAC blocks are often used in load-bearing wall systems, providing structural support to buildings.

Firewalls: The fire-resistant properties of AAC blocks make them suitable for constructing firewalls, enhancing the safety of buildings.

Soundproofing: AAC blocks have good acoustic insulation properties, making them ideal for soundproofing walls in buildings like recording studios or residential units.

Foundation Walls: AAC blocks can be used in foundation walls, contributing to the stability and durability of the building’s foundation.

Greenhouses: The thermal insulation properties of AAC blocks make them suitable for constructing greenhouses, providing a controlled environment for plant growth.

Retaining Walls: AAC blocks are used in the construction of retaining walls due to their strength and ability to withstand lateral pressure.

These diverse applications showcase the versatility, durability, and energy efficiency of AAC blocks, making them a popular choice in modern construction.

History Of AAC Blocks?

The lightweight precast foam concrete building material known as Aerated Concrete (AAC), also referred to as Autoclaved Cellular Concrete (ACC) and Autoclaved Lightweight Concrete (ALC), was created in the middle of the 1920s and offers a number of advantages including structure, insulation, fire and mold resistance, and more. As it is composed of 65–70% sand and fly ash (by weight), it is also an environmentally beneficial product. Due to their numerous attractive qualities, AAC blocks have become extremely popular in Northern, Western, and Southern India. Almost 80% of new buildings uses AAC blocks instead of the more conventional fried clay bricks. Since 2012, it has been gaining traction in the Northeast with the intention of totally eliminating the usage of conventional fried clay bricks.

Midway through the 1920s, Dr. Johan Axel Eriksson, a Swedish architect and inventor, collaborated with Professor Henrik Kreuger at the Royal Institute of Technology to improve AAC. In 1924, the process was patented. 1929 saw the start of production in the Swedish town of Yxhult. Later, “Yxhultbolaget” developed into Ytong, the first registered construction materials brand in history. Josef Hebel, a technician and creator of the company based in Memmingen, is the man behind the second major international cellular concrete brand, Hebel. In 1943, Germany’s first Hebel plant began for business.

Ytong autoclaved aerated concrete was first created in Sweden using alum shale, which was advantageous to employ in the manufacturing process due to its flammable carbon concentration. Sadly, there is not much natural uranium in the slate resources used to make Ytong in Sweden. As a result, the material releases radioactive radon gas into the structure. After 1975, Ytong used new recipes containing only quartz sand/fly ash, calcined gypsum, lime (mineral), cement, water, and aluminum powder to produce a new type of aerated concrete blocks that did not contain alum slate. As a result, the issue of radon exposure from this raw material was resolved. Since then, all producers worldwide have been using cutting-edge techniques to produce this white autoclaved aerated concrete using identical recipes.

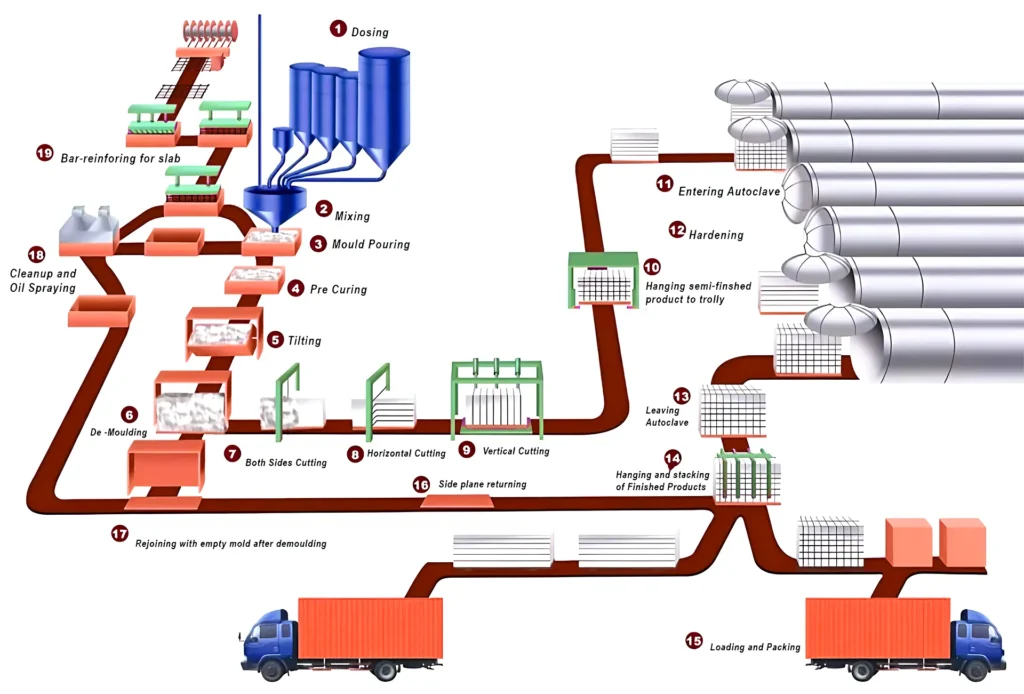

Raw Material Preparation:

The first step in the manufacturing process of AAC blocks is the preparation of the raw materials. The materials used in the process are cement, lime, fly ash, gypsum, water, and a small amount of aluminium powder. The raw materials are mixed in the right proportions using a mixing machine.

Mixing:

Our fullly automated batching plant enables accurate dosing, weighing and mixing of all the raw materials. The next step is mixing the prepared raw materials. The mixture is placed in a large vessel and mixed thoroughly until it forms a homogeneous mixture.

Aeration:

Once the mixture is prepared, it is poured into moulds and allowed to be set for a few hours. During this time, the aluminium powder reacts with the other materials in the mixture, producing hydrogen gas. This process is called aeration and results in tiny air pockets throughout the material, making it lightweight and porous.

Curing:

After the blocks are poured into moulds, they are left to cure for a few hours. Once the blocks have hardened, they are removed from the moulds and cut with wires into blocks with precision accuracy. Then the blocks are placed into an Autoclave.

Autoclaving:

The blocks are then subjected to steam and heat in an autoclave. The autoclave is a high-pressure chamber that exposes the blocks to high temperatures (approx 180-190 °C) and steam, which helps to further harden and strengthen them. The autoclaving process takes several hours and is critical in ensuring that the blocks are durable and resistant to damage.

Sorting And Packaging

Once the blocks are removed from the autoclave, they are ready for use in construction. Each block is sorted for any damages and breaks and then packed perfectly for delivery. They can be easily cut, drilled, and shaped using standard tools, making them versatile and easy to work with.

CONECC